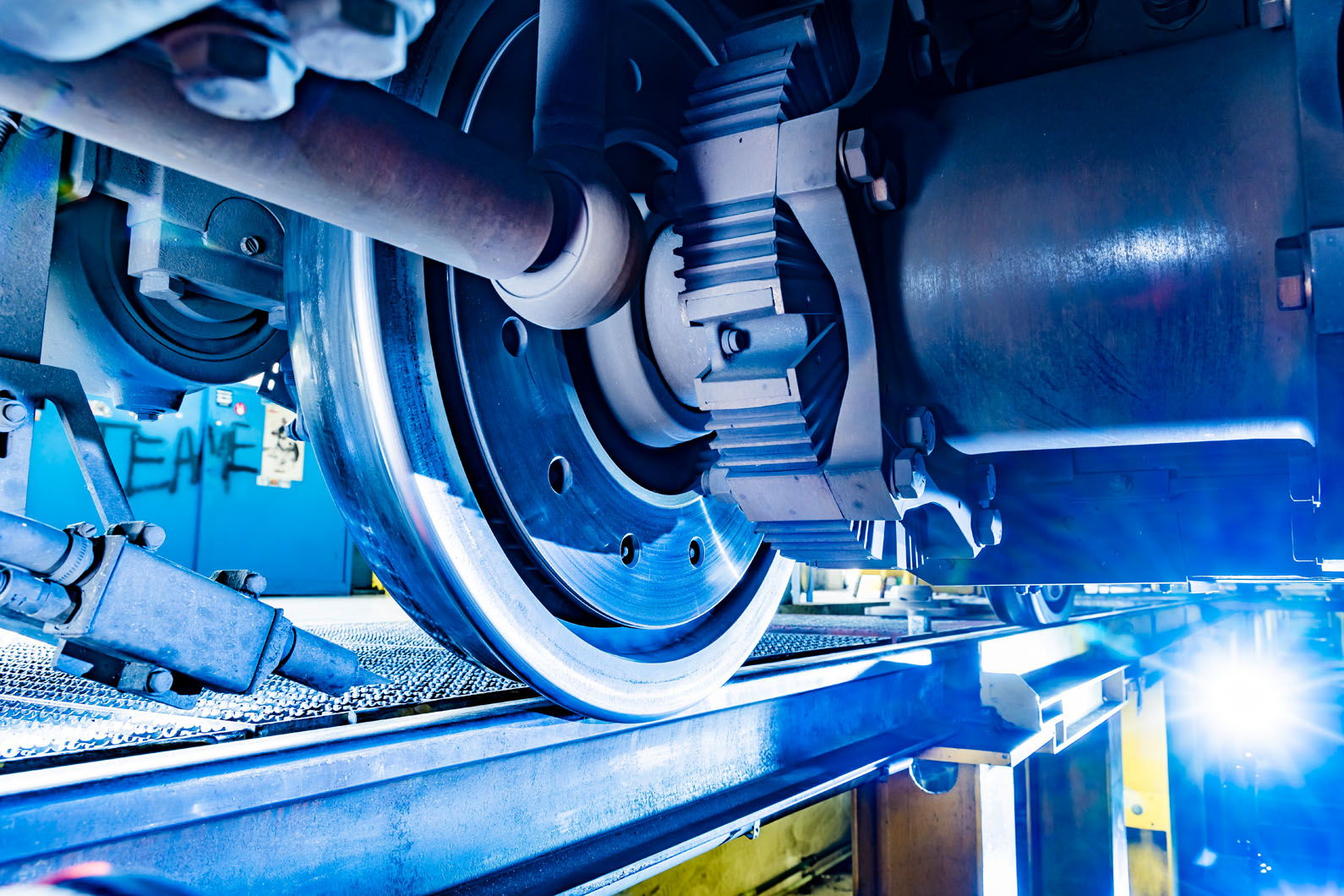

A new chapter for 2026

A new chapter for 2026

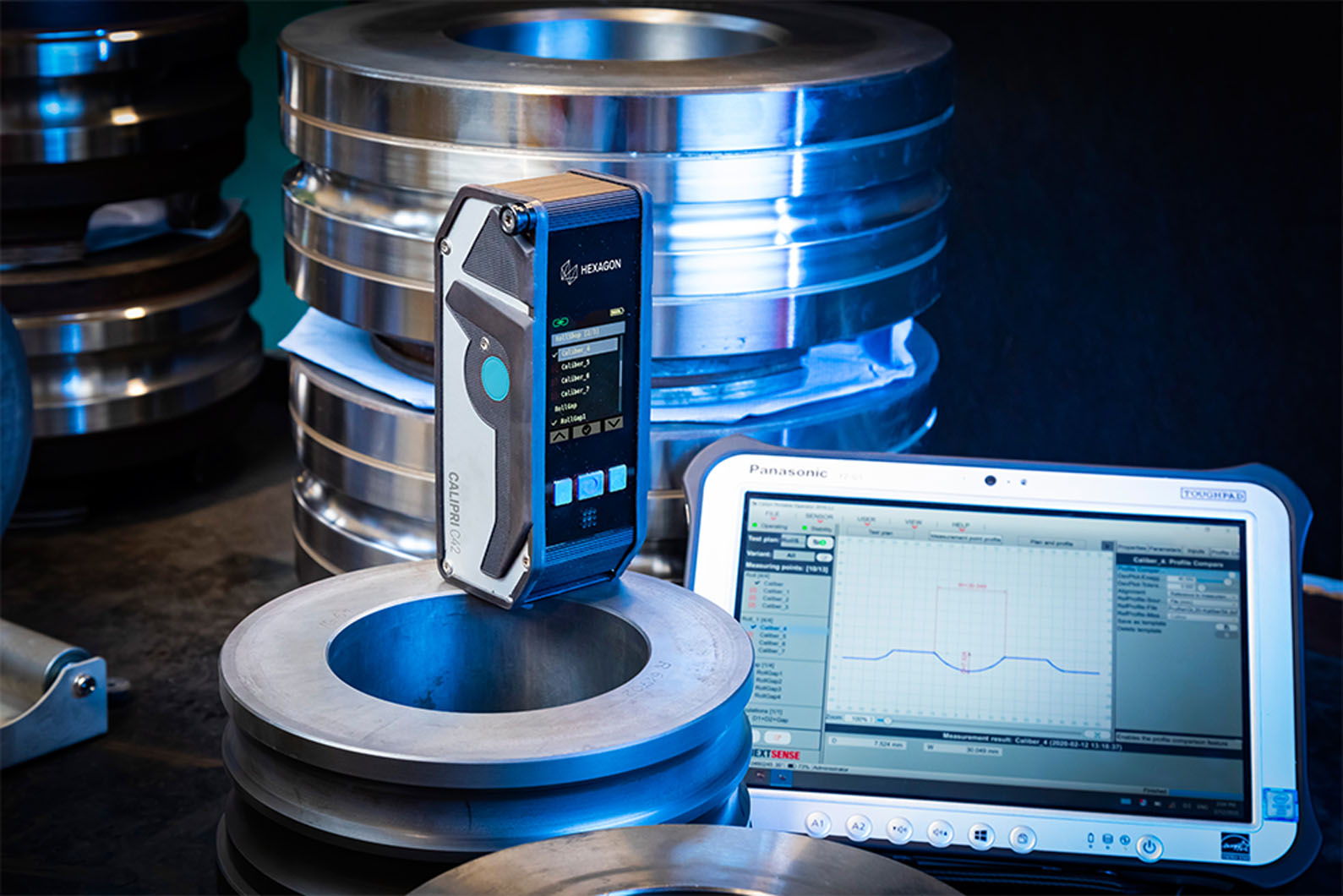

From January 1, 2026, we will operate as *Business Unit CALIPRI* within the Hexagon Group. NEXTSENSE GmbH will remain as the legal entity, without any external brand presence. Our brand presence becomes clearer and more consistent: Hexagon as the corporate brand and CALIPRI as the product brand.

CALIPRI will continue to stand for quality, precision, excellent service, and ease of use — and we look forward to shaping the future together.